February 2018

Dr Martin Grabert, CEO, Montroix Pty LtdOcean plastics and the SDGs

The era of bioplastics is upon us. New innovations and commercial opportunities in bioplastics promise to make significant progress on the UN’s Sustainable Development Goals (SDGs).

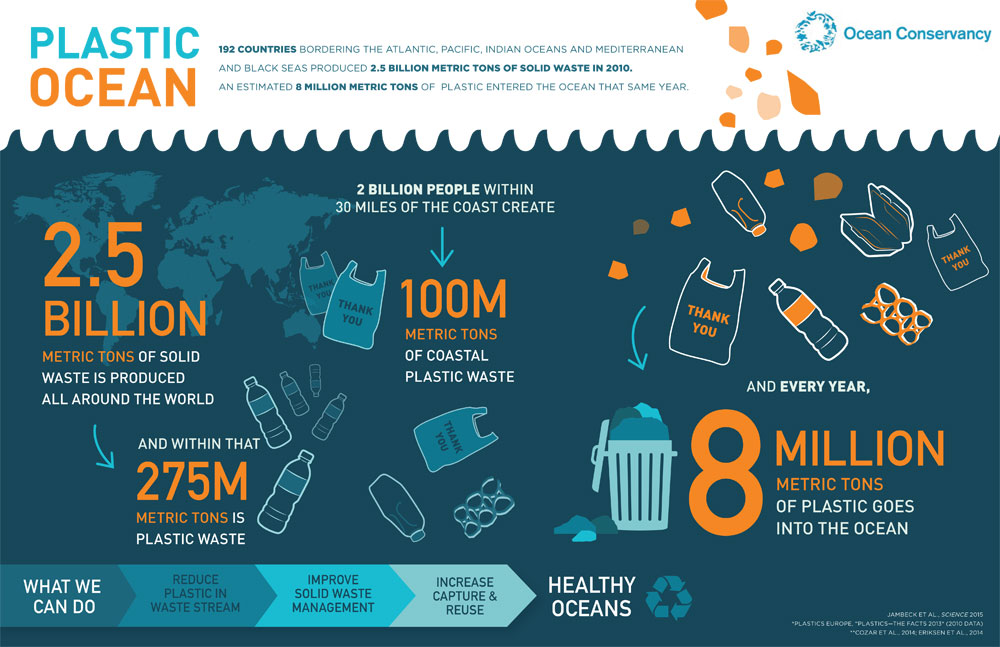

It is a sad fact that we throw 8 million tonnes of plastic waste into our oceans every year. A great amount of this plastic has already formed a new ‘dynamic’ continent in the Pacific, and the natural shredding process at sea will leave all this waste to become part of our food chain in the form of micro-plastic. The prospects of this environmental disaster are daunting – we have to do something.

Apparently, we can’t live without plastics. Since they are so useful and economically important, how can we produce and use plastics without polluting our natural environment?

One solution – bioplastics – is a genuine ‘win-win’ which can simultaneously tackle ocean pollution, agricultural waste, and climate change – and also provide new industries and employment in regions that need them.

What are bioplastics? Plastics made from biological matter, including organic waste.

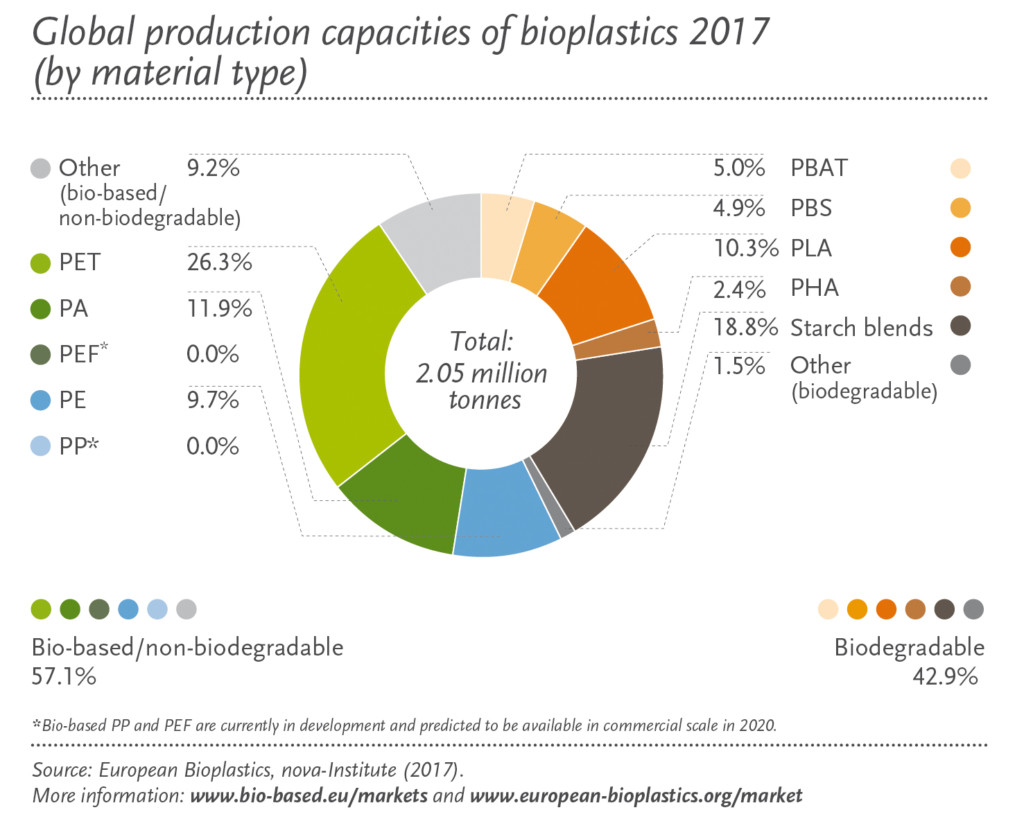

Are they a realistic option? Yes, they are. Bioplastics come in many forms and shapes. Polyhydroxyalkanoates, or PHAs, are polyesters produced by bacteria in nature, to store carbon and energy. These plastics are completely bio-degradable in both soil and the marine environment.

Since the bacteria producing the plastic thrive on substrates of agricultural waste, they can become a value-add component to a closed-cycle green economy. Bioplastics from PHAs are ideal for packaging (bottles and containers) and have a shelf life of up to 2 years. Food products packaged in fully bio-degradable bioplastic containers could contribute to the closed-circle green production chain.

Producing PHA from large volumes of solid green waste is beneficial, however the bacteria require a pre-treatment step to convert the green solid waste into a useful feedstock. One solution to be investigated is feedstock based on the residual slurry from bio-gas production.

PHAs were first discovered by the French chemist Lemogine in 1926, but further advancement was stalled when cheap and abundant plastics made from petrochemicals took off. In the 1980s research picked up the thread again and several companies brought products to the marketplace. Because of the low price of crude oil, production of bioplastics was slightly more expensive than for commodity plastics, and even at present the technology remains in its well contained niche. I think it’s time to change that – and it’s also a change whose time has come.

PHAs offer unique benefits for end-of-life disposal, in line with increasing government bans on landfills and the strong drive towards full plastic recycling in Europe and the rest of the world. PHAs are both compostable and biodegradable in soil, riverine and marine environments. Other biodegradable polymers such as polylactic acid (PLA) are compostable, but remain in marine environments for up to a thousand years.1 This is an important difference, considering polymer pollution in the marine environment is particularly harmful and dangerous. It is estimated that 100 million tonnes of conventional plastics cause environmental damage of approximately US$13 billion per year.2

Since PHAs are naturally occurring polymers it can be produced in different ways using particular strains of bacteria and can be used in a wide range of applications, from food packaging to medical implants.3

Initially, the commercialisation of PHA was hindered by relatively high production costs, low yields and limited availability, making it difficult to compete with its petrochemical counterparts. However, recent breakthroughs have found certain bacteria that are capable of producing PHA from a range of carbon sources including waste effluents, plant oils, fatty acids and other waste. This greatly broadens their appeal – for example, using agricultural waste materials as feedstock for PHA production will have the dual benefit of reducing PHA costs and reducing the cost of waste disposal.

PHAs degrade fully under almost all conditions, breaking down into water and small amounts of CO₂. In general, PHA will degrade faster in regions that have abundance of PHA-degrading microorganisms.4

In the Pacific islands, for example, the socio-economic aspects of the introduction of PHA technology could have even wider impacts. Closing the green production circle could become a compelling marketing campaign for the organic produce they export to the globe. This alone would justify the investments into such an innovative and sustainable technology platform. In addition, it would reduce the necessity to import petroleum-based plastics and, as importantly, would create a significant number of jobs in producing the PHA – collecting and processing agri-waste to feedstock (and eradicating invasive plants), running the fermentation process and the actual plastic production. A real and tangible advancement towards the SDGs.

In short, PHA bioplastics in the form of bottles or food containers could help us to reduce plastic contaminants in the oceans, reduce oil dependency and create local industries and employment. A win-win solution for all. Let’s do it, now!